CSAP - mount and connect

Noliac Technology

Mounting

CSAPs present electrodes on top and bottom surfaces. They may be mounted either by mechanical clamping or gluing.

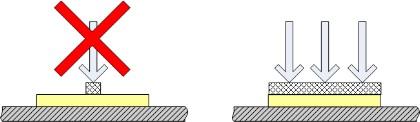

Figure 1. Clamping and gluing options

Mechanical clamping1. Axial stress on CSAPs must be controlled. Too low pressure can lead to slippage whereas too high pressure can damage the ceramic.

2. If clamping is used, the stiffness of the loading mechanism in the actuation direction shall be as low as possible in order not to hinder the movement of the actuator.

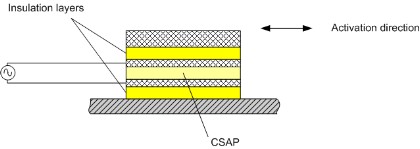

Figure 2. Activation in the case of clamping

3. The force must be applied on the full surface of the actuator in order to ensure a good load distribution. In particular when applying the pressure, the contact surfaces have to be sufficiently flat or compliant.

Figure 3. Uneven and even loading

4. It can be necessary to insulate the contact surfaces from the rest of the structure. This can be achieved by adding inactive ceramic plates in the structure.

Figure 4. Method for complete electrrical insulation

5. If glued it is important to ensure a very thin glue line between the CSAP and the substrate. This is generally ensured by using low viscosity glue. A pressure, e.g. 2 - 3 MPa, shall be applied during the curing process.

Epoxy glues are well suited for gluing piezoceramics however several alternatives exist. Please contact us if you need support on selection of appropriate glue for your application.

Figure 5. Preferred gluing layout

Electrical connection

External electrodesSince CSAPs can be used with symmetrical electrical supply, both electrodes are identical. The direction of operation is indicated by the chamfers.

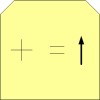

Sign convention: A positive voltage on one electrode leads to a relative displacement of this electrode towards the chamfered edge.

Figure 6. Sign convention

Electrical connection to the external electrodes can be achieved by mechanical contacts, soldering, gluing with electrically conductive glues or wire bonding.

Mechanical connections

Mechanical connections can be arranged by e.g. copper springs contacted to the external electrodes. CSAPs are provided with gold plated electrodes for optimal electrical contact and to avoid oxidation of the electrodes. For demanding applications, it might be necessary to have both contacts gold plated.