KEMET-TOKIN - Resin Coated Ring Actuators

Piezoelectric Multilayer Ring Actuators

AER Series

Outline

KEMET’s multilayer piezoelectric actuators are produced based on our unique element structure design and piezoelectric ceramic materials with high electrostrictive factors. Compared to conventional piezoelectric actuators, they are smaller in size but can generate higher displacements and forces at low voltages.

The Resin Coated, Ring Shape AER series actuators feature compact size for applications such as ultra-fine positioning mechanism and drive sources.

Data Sheet for AER Ring Actuators

Data Sheet for AER Ring Actuators

Standard Parts List

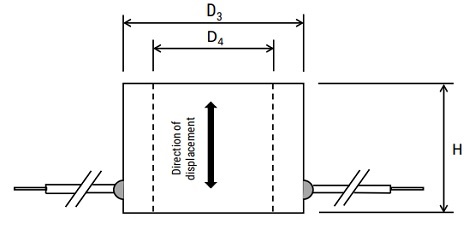

| Prod. Model | OD1 | ID1 | H | Free Stroke 150Vdc | Block Force | Res. Freq | Cap | Ins. Res. |

|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | [µm] | N | kHz | µF | MOhm | |

| AER13.6X10X10 | 13.6 | 10 | 10 | 9.1±1.5 | 2,200 | 138 | 2.1 | 10 |

| AER13.6X10X13.5 | 13.6 | 10 | 13.6 | 13.2±2.0 | 2,200 | 102 | 2.8 | 10 |

| AER20X15.4X10 | 20 | 15.4 | 10 | 9.1±1.5 | 4,200 | 138 | 3.7 | 2 |

| AER20X15.4X13.5 | 20 | 15.4 | 13.5 | 13.2±2.0 | 4,200 | 102 | 5.3 | 2 |

Basic Outer Dimensions

Features

Special ceramics developed by TOKIN are used in piezoelectric ceramic elements. As compared with conventional actuator elements, TOKIN's multilayer actuators have the following advantages:

- Ring shape.

- Operating temperature range from −25°C to +85°C

- High-speed response: Driving up to about 1/3 of self-resonant frequency (in several ten kHz)

- Low power consumption: Can be retained at the leakage current (100?A or less).

- RoHS/REACH compliant

Advantages over electromagnetic actuators

- Faster response

- Higher resolution for positioning

- Large generated force

- Low power consumption

- No electromagnetic noise

Advantages over bimorph piezoelectric actuators

- 7 times the energy conversion efficiency of the bimorph type actuator

- Lower power consumption

- Large generated force

- Stable displacement, and reduced shift and creep phenomena

- 100 times the response speed of the bimorph piezoelectric actuator

Advantages over stacked piezoelectric actuators

- Compact size (less than 1/10 the specific volume of the stacked piezoelectric actuator

- Low drive voltage

- Easy to use

- Inexpensive

Applications

- Actuator of shaker, positioning of light source

- Robot, positioning of equipment, pressure sensor

- Positioning of stage, actuator of autofocusing, actuator of shaker and damping system

- Polarization control, wavelength control

- 100 times the response speed of the bimorph piezoelectric actuator

- Micropump, ultrasonic transducer, manipulators

- Fine positioning