CMA and SCMA - mount and connect

Noliac Technology

Mounting

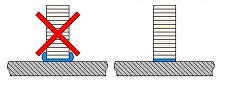

CMA's and SCMA's are usually lapped on top and bottom surfaces (perpendicular to the polarisation direction) in order to obtain flat and parallel surfaces for mounting. CMA's and SCMA's may be mounted either by mechanical clamping or gluing.

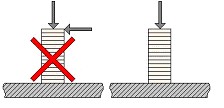

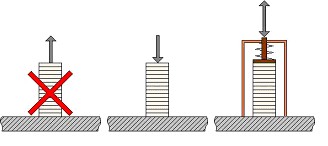

CMA's and SCMA's must only be stressed axially. Tilting and shearing forces must be avoided.

CMA's and SCMA's without preload are sensitive to pulling forces. It is recommended to apply a pre-load in order to optimise the performances of the actuators.

The force must be applied on the full surface of the actuator in order to assure a good load distribution.

- Adding Kapton foil on the metallic surfaces

- Having inactive ceramic plates between the CMA and the metal plate.

SCMA's are manufactured with top and bottom isolating ceramic end plates.

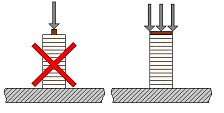

If glued it is important to ensure a very thin glue line between the CMA (or SCMA) and the substrate. It is recommended that a pressure, e.g. 2 - 5 MPa, is applied during the curing process.

Epoxy glues are well suited for gluing piezoceramics however several alternatives exists. Please contact us if you need support on selection of appropriate glue for your application.

Important remark:

To avoid significant loss of performance, the mounting of the CMA's and SCMA's should avoid mechanical clamping and/or gluing on the sides of the actuator.

Please note:

During manufacturing or handling, minor chips on the end-plates can appear. Minor chips cannot be avoided. However, such chips do not affect performance.

Electrical connection

External electrodes

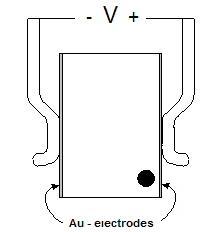

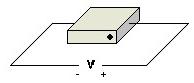

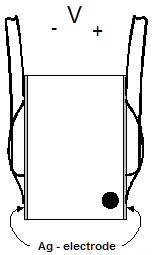

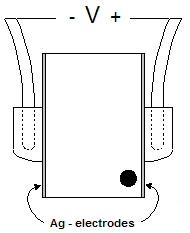

The positive electrode is marked with a black spot. As standard the external electrodes are screen printed silver. Other materials, e.g. gold or silver/palladium are available on request.

Electrical connection to the external electrodes can be achieved by mechanical contacts, soldering, gluing with electrically conductive glues or wire bonding.

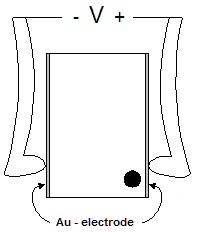

Mechanical connections

Mechanical connections can be arranged by e.g. copper springs contacted to the external electrodes. It is recommended to use external electrodes of gold in order to eliminate oxidation of the electrodes followed by poor electrical contact to the mechanical connections.

There are two possibilities:

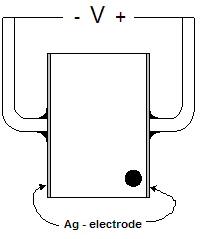

Gluing wire contacts

Electrical connection can also be arranged by gluing wires to the external silver electrodes. We recommend a two component soft epoxy glue with 75% silver content and a curing temperature below 150ºC to avoid depolarization of the PZT. Gluing is recommended as alternative to soldering the wires when the PZT is working at high frequency or the PZT is subjected to high thermal variations from the environment as for example in diesel injection systems. It is recommended to use external electrodes of silver in order to archive good electrical contact between glue and electrode.

Wire bonding contacts

Electrical connection can be done by wire bonding gold wires to the external gold electrodes. We recommend external gold electrodes as gold generate a thin oxidation layer, that has to be penetrated in the rubbing process ensuring a better mechanical and electrical contact.