Definitions

Noliac Technology

In the world of piezoelectric devices there are a number of definitions which are important to understand:

|

AgingChange of material properties with time. Aging of piezoelectric ceramic occurs very rapidly in the first few hours after poling. After a few days the changes in the material properties are very small and decrease logarithmically. Indeed in ferroelectrics, the aging of piezoelectric properties is often logarithmic. E.g.:

Where to is an arbitrary time when the measurement has started, and A is the “aging rate” constant, specific to the composition, the microstructure, and the processing history of the element. An origin of aging is in internal stresses such as those built in the material during poling. These stresses may be relaxed by domain reorientation during time. Another source of aging is point defects that exist in many piezoelectric ceramics (vacancies of lead and of oxygen) and are mobile with time and may build internal fields that restrict domain wall movements. Space charge in grain boundaries may also contribute to aging. [back to top] |

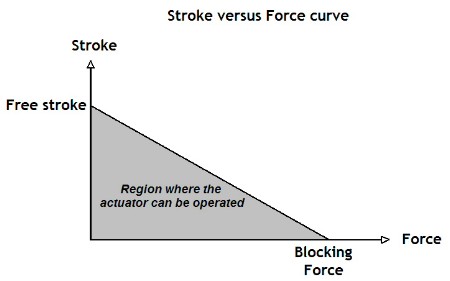

Blocking force & free strokeThe blocking force and the free stroke that can be obtained at the maximum applicable voltage, are probably the two most important properties to be considered, when evaluating if a given actuator device can meet the requirements in an application. That's why piezoelectric actuators are usually specified in terms of their free stroke and blocking force.

Please note: In practice, a piezoelectric actuator must move and exert a specified force, which determines its operating point on a stroke versus force curve. The force developed at maximum deflection and at zero deflection are respectively zero and the blocking force. All other values of simultaneous displacement and force (for a given voltage level) are determined by a line drawn between these 2 points on the stroke versus force curve. Work is maximized when the deflection performed permits one half the blocked force to be developed. This occurs when the deflection equals one half the free deflection. |

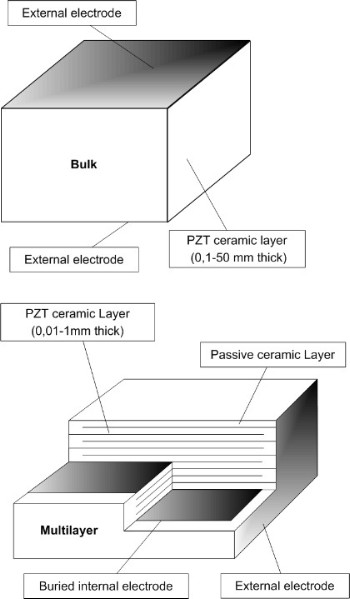

Bulk / monolayer vs. multilayer

|

Bus wireA wire with multiple bends soldered on stacked ceramic multilayer actuators to electrically connect all the multilayer actuators in the stack. |

CapacitanceThe capacitance is a quantity dependent on the type of material and its dimensions. Capacitance is calculated by multiplying the relative dielectric constant K by the permittivity of free space ?o (?o=8,9 x 10-12 Farads/meter) and electrode surface area A, then dividing by the thickness t separating the electrodes. Units are expressed in farads. Piezoelectric actuators with many thin dielectric layers connected in parallel (multilayers) can be of quite high capacitance, especially those for low operating voltage. A capacitance in the range of 1-10µF is not unusual. This has to be taken into consideration when developing the driving electronics, or matching an actuator to existing driving electronics. Please note: The electrical capacitances stated in the data-sheets are measured for “small signal values”. Capacitance of piezoelectric actuators varies with voltage, temperature and load. Therefore the stated capacitances are only a rough number. Capacitance data are needed to value the electrical currents or powers required for a distinct dynamic reaction. Please take therefore into account at least a factor 1,5, when checking for a proper power supply. |

Closed loop controlThe actuator is used with a position sensor, providing feedback to the position servo controller compensating for non-linearity, hysteresis and creep of the piezoelectric actuator. |

Coupling factorA dimensionless number defined as the square root of the ratio of energy stored in mechanical deformation to the electrical energy needed to produce that deformation. |

CreepPiezoelectric materials exhibit a creep effect i.e. the material continues to expand for some time upon charging. Correspondingly the material does not immediately return to the initial strain level upon discharging. |

Curie TemperatureAs the operating temperature increases, it gets easier to depole the piezoelectric material. Complete and permanent depoling occurs at the material's Curie temperature. Each ceramic has its own Curie point. When the ceramic element is heated above the Curie point, all piezoelectric properties are lost. In practice, the operating temperature must be substantially below the Curie point. |

Dielectric constant, relativeThe ratio of the permitivity of the material ? to the permitivity of free space ?0 at low frequencies well below any mechanical resonance of the structure. The relative dielectric constant is important because it affects the capacitance of piezoelectric component and therefore the electric current required to drive them at high frequencies. |

d constantA constant that represents the piezoelectric sensitivity by relating the mechanical strain with applied electric field. It is defined as the ratio of strain to electric field. |

Dissipation factorThe dissipation factor is a number that specifies the dielectric losses inherent in a piezoelectric material. It is defined as the tangent of the loss factor (tan ?), or the ratio of effective series resistance to the effective series reactance, expressed in percent. The dissipation factor is usually specified for low electric fields and at a frequency of 1000Hz. In static operation virtually no heat is generated with voltage applied, but when the voltage is modulated at high frequency heat is generated inside the material in proportion to the dissipation factor. The associated temperature rise is often the limitation on the power handling capability of the material. |

HysteresisAll piezoelectric materials exhibit a mechanical hysteresis as the strain does not follow the same track upon charging and discharging. The hysteresis is expressed as the maximum strain divided by the maximum difference between the two tracks. The mechanical hysteresis depends on the type of ceramics and can vary from 4% to 20%. Please note: If it is important to know the exact displacement of the actuator at a given voltage, it is then recommended to use a feedback system, e.g. strain gauge mounted on the actuator (static applications) or an integrated piezo-sensor (dynamic applications). Another approach to strongly reduce the hysteresis effects consists of driving the piezoelectric actuator by controlling the transferred charge on the electrodes. |

Maximum free displacementDisplacement measured at room temperature, with no mechanical load and at maximum recommended voltage. |

Maximum recommended operating temperatureMaximum temperature the actuator should be exposed to during operation or handling – even short term. |

Mechanical factor QmThe mechanical factor Qm is the ratio of reactance to resistance in the series equivalent circuit that represents the mechanical vibrating resonant system. The mechanical factor Qm is related to the sharpness of the resonant peak. |

Multilayer piezoelectric actuatorMultilayer piezoelectric ceramic actuators are electromechanical devices for generating movements in the micrometer range. The conversion of electrical energy into mechanical motion takes place without the generation of any magnetic field or the need for moving electrical contacts. Piezoelectric devices are capable of response times in the microsecond range and can develop blocking forces up to several KN and their stroke varies approximately linearly with applied voltage. |

Open loop controlThe actuator is used without a position sensor. Displacement roughly corresponds to the drive voltage. Creep, non-linearity and hysteresis are not compensated for. |

Piezoelectric ceramicCeramics are inorganic non-metallic materials. Piezoelectric ceramics differ from piezoelectric crystals in that they must undergo a poling procedure for the piezoelectric phenomenon to occur. For each material there is a characteristic Curie temperature. Above the Curie temperature electric dipoles inside the material exist in random orientations. When a strong electric field is applied they become aligned in the direction of the field and remain partially aligned after the field is removed, provided the material is first cooled well below its Curie temperature. In this state the ceramic is said to be poled. When the poled ceramic is subjected to a small electric field the dipoles respond collectively to produce a macroscopic expansion along the poling axis and contraction perpendicular to it. |

PZTAn acronym for Lead Zirconate Titanate. |

Recommended voltage rangeThe actuators should not be exposed to any voltage outside this range during operation – even on short term. |

StrainThe strain is the ratio of the change in length to the length:

|

WireThe wires soldered to the stacked ceramic multi-layer actuators are single or multi-core leads with a specified length and a gauge using AWG. |