CMBR Stacking

Noliac Technology

Ring benders may be stacked to multiply performance by gluing on a “mounting ring” with nonconductive epoxy glue and put on top of each other using a special part inserted in the centre hole.

The special part of selected material inserted in the centre hole is called “centre hole insert”. The mounting rings may be manufactured in aluminium, but other material such as ceramic for instance can be used. In the eventuality of operation in a non quasi-static mode, the overall resonance frequency of the assembly has to be watched out as it will noticeably decrease with the assembly height.

Stacking

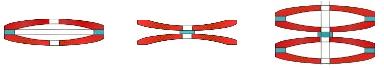

Two different configurations can be considered when stacking only two ring benders:

1. Face to face (F2F) which requires the use of a mounting ring.

2. Back to back (B2B) which requires the use of a centre hole insert ring.

Stacking of more than two CMBR is operated as a combination of both F2F and B2B.

It might be necessary to compensate for the axial play. Maximum height of the stack will depend on guiding.

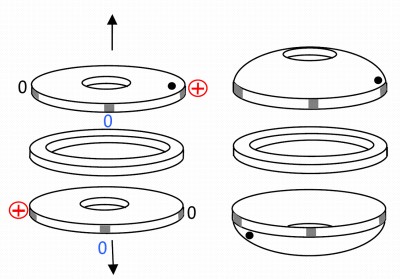

1. Face to face - Mounting ring.

Gluing of the CMBR on mounting rings must be operated as explained in Technical support - CMBR - mount and connect.

Gluing of the CMBR on mounting rings is likely to reduce overall performances available from the ring bender as a minor clamping of its active area is to be expected.

Due to the non-planarity of the ring benders, it is recommended to use rings and not discs.

Face to face mounting with mounting ring

Particular attention must be paid to the material used for the mounting rings, as a conductive material could create a short circuit if in contact with CMBR external electrodes (chamfering of either the actuator or the mounting ring is an option).

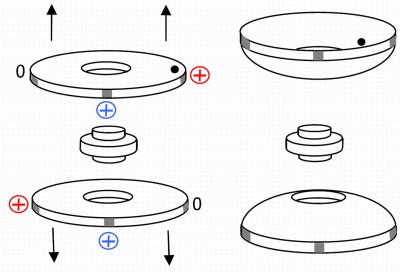

2. Back to back - Centre hole insert

Different scenarios (gluing or mechanical clamping) are possible for the centre hole insert. Noliac recommends gluing of a non conductive workpiece.

Gluing of the CMBR on mounting rings must be operated as explained in Technical support - CMBR - mount and connect.

Gluing of the CMBR on mounting rings is likely to reduce overall performances available from the ring bender as a minor clamping of its active area is to be expected.

Back to back mounting with centre hole insert ring

Pre-stressing of the assembly is a solution that can avoid gluing centre hole parts.

Assembly wiring

Stacking of two benders

Suggestion of wiring in the given configurations is as follows:

| Front to front | Back to back |

|

|

*see Technical support - CMBR - mount and connect*

Stacking of more than two CMBR

A particular care has to be paid to cables if the assembly is made of more than two benders.